What is Metal spinning.It is the art of raising sheet metal disks into contoured forms by turning on a lathe. A tool pressed into a soft piece of metal makes a dent. If the tool is held against this dent and the metal is rotated about a center, the dent will turn into a groove, extending entirely around the object. It may then be said to have been “spun” into a changed form.

To secure this result, however, it is necessary that the metal in bending, shall meet a resistance in the form of a mold around which it can take shape. This shape, which is called the chuck, is usually made of wood. A knowledge of wood turning is of great help to the prospective metal spinner.

A Brief History Of Metal Spinning

The Chinese originated metal spinning somewhere about the beginning of the tenth century of the Christian era. However, our present-day knowledge of the metal spinning craft has come from the Greeks and the Romans, who spun many of their household utensils from pewter.

During the reign of King Edward III metal spinning was introduced into England as a trade. Metal spinners formed their own guild systems to protect the craft against inferior workmanship.

About 1840 metal spinning was introduced into the United States, and before long there were many small shops that were turning out articles made from pewter and sterling silver. At the present time there are many big concerns in our larger cities turning out articles spun on the lathe in the same manner as the original craftsman.

What IS Metal Spinning Lathe

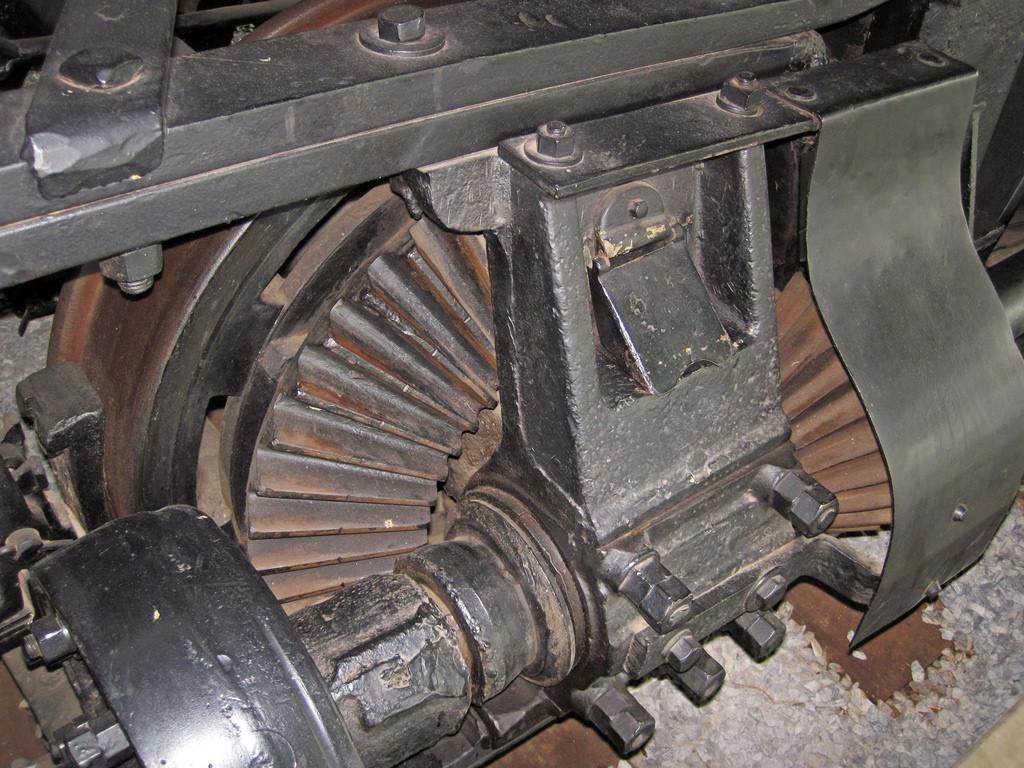

For most varieties of metal spinning the lathe should have a variable speed head stock capable of taking a heavy end thrust. Considerable friction is developed in metal spinning, and to do good work a constant flow of power is necessary. Some spinning lathes have a variable unit-type, motor-driven head stock and can be adjusted to any speed from 800 to 2400 r.p.m., as may be required by the size and particular nature of the metal being spun. In these lathes the head stock should also have a substantial thrust bearing to withstand a heavy constant pressure.

An ordinary faceplate may be used to hold the chuck while spinning. If enough face plates are not available, it is much more convenient to bore a hole in the chuck and tap it to fit the lathe spindle.

The ordinary tail stock found on most wood lathes will be found satisfactory for the average spinner. It will, however, be necessary to use a spinning center in place of the regular center.